What is a BOPMS for Farm Improvement? (a Mind Map Based Explanation - By Tayo K. Solagbade) - Video and Text Transcript

lTIP: The mind map based video explanation now offered from this page is actually a re-RECORDING to replace the original version that (strangely) became "Not Found" in my Youtube channel]

Do you run a farm business, or plan to start one? If yes, adopting the ideas below can save you time, effort, and lots of money - in the short, and/or long run. This article is based on transcripts of my video explanation, using a mind map, of key components of a Best Operating Process Management System(BOPMS)™.

At the end, I supply a link to a page where you can request download link access to the full length video. There, you will also find links to over 10 articles that offer more information.

What Does a BOPMS™ Entail - and How Can It Help You?

If you’ve been reading my writing a while now, you’ll know I often advocate adopting best practice systems.

As a result, sometimes I get phone calls from farm owners, especially poultry layer operators. They often want to know what exactly the BOPMS™ I talk about entails.

Some say they'd like to have it done for them.

It has a number of components - see the boxes in the mind map below (3 yellow ones, and 2 uncolored).

VIDEO: MIND-MAP BASED EXPLANATION OF BOPMS™ FOR FARM BUSINESS MANAGEMENT- BY TAYO K. SOLAGBADE

Click here to watch a screen shot video in which I use a mind map to explain the Best Operating Process Management System (BOPMS)™ for Farm Business Performance Improvement - based on its components [Note that www.thefarmceo.net displayed in the mindmap used in the video has since been retired and replaced with www.iff.tayosolagbade.com]

Basically those descriptions in the boxes refer to the key components of a BOPMS™

I came up with the concept myself - based on Best Practice World Class Process Management principles. And what I do basically is to give prospective clients 2 major options, in terms of implementing it.

It's either they...

1. Develop and Implement an Enterprise Information System (EIS)

This option is a simpler alternative. The 3 yellow boxes are relevant to this option.

a. Process Performance Evaluation and Control

b. Micro Income/Expenditure Calculation

c. Enterprise Information System

It involves having a software based system setup for you, to monitor your farm KPIs i.e. Key Performance Indicators.

You would then use the reports generated by such an application to achieve better farm management planning and decision making.

Typical KPIs for a poultry enterprise, that a good EIS would measure, are described (with formulas stated) in my popular article titled Practical Poultry Farm Business Performance Calculations.

...or they do 1. above AND also...

2. Establish & Entrench Standard Operating Procedures - While Exploring Variable Costs Reduction

On the other hand, you could go the full hog and implement ALL five BOPMS™ components, by adopting the remaining two:

a. Variable Costs Reduction Initiatives

b. Workplace Organisation/Best Practice Management to Entrench SOPs

For those who are interested send me an email, and I’ll send you a list of articles that talk about this in more detail.

You Can Run Your Farm Business Without Tears...and LESS SWEAT!

But basically we’re talking about having an automated system for tracking the performance indices on your farm. This would enable you not have to stay every second on the farm monitoring what your operatives are doing.

To do that you need to have a specific kind of process record form designed, based on the manner in which you run your farm.

So basically I normally have to visit farms to find out how they operate, and then I design a form that enables them capture the relevant records.

The software I then build for them using Excel Visual Basic is called an Enterprise Information System.

So they would - on a daily, weekly, or monthly basis (preferably daily), make entries using the record form I design, into the application/the EIS.

And they would be able to easily determine the performance indicators like Hen Day Percentages, Egg to Feed ratio, Mortality Rates, and Feeding rates (grammes per bird).

Some of these indices can be quite useful in predicting, or anticipating, or proactively determining things that are about to go wrong.

For instance, a drop in Hen Day Production percentages could tell you a lot of things. Depending on how long your birds have been in lay, values should be about 70% or higher.

Feeding Rates should hover around 100 to 110 g/bird: Too low would suggest underfeeding, with consequent impact on egg laying performance. Too high would amount to over feeding, with implied needless waste of feed (reflected in lower number of eggs per bag fed i.e. egg to feed ratio). Neither is good.

When you don’t collect the records on the record forms, and post them into a software that trends them in form of charts, you may not see that.

When you collect eggs and manually record your numbers in a book, such subtle trends will not be readily apparent to you.

I say this based on over 20 years of developing applications for process monitoring and control.

Just last week, I got two farm managers nodding vigorously in understanding, as I coached them to post their data into the application I built for their farm.

As the data for each cage line was punched in, they saw the various KPIs appear. And when we began generating the report tables with charts, the plotted lines per cage and per pen for each day, week, and month we chose gave revealing trends.

This instantly triggered a discussion amongst them, as they tried to come up with accurate explanations of the variances noticed.

One of them said "Ah, this software will be quite useful."

I had no need to say more.

The interesting thing is that to some extent, most farm owners can use MS Excel, by themselves, to track the KPIs too.

However, where my apps add value is their use of complex and elaborate formulas and functions, and as well as vba automation.

Then of course there's the ready-to-print report formats.

But you can always start with the basics. That would be better than doing nothing - which would amount to working blind!

A Word of Warning About GIGO - Garbage In Garbage Out

You could have a software that your personnel make entries into.

But how can you be sure data hand-recorded on the forms used to post entries into the software are real or accurate values?

We talk about GIGO when it comes to computers. And never has it been more applicable than when it applies to farm operatives – who can get so busy they “forget” lots of things.

When that happens, some may try to remedy the situation by recording “guesstimates” – which could over time produce unreliable results.

In fact many farm owners often get surprised (unpleasantly) by their farm businesses.

One day the birds are doing very well, laying at 82% HDP. Next day you get a 55% HDP report, and you don’t know what happened in between.

Now, that‘s why you need to have Standard Operating Procedures.

In the Mind map Box Titled "Workplace Organisation/Best Practice Management to Entrench SOPs", you’ll see I have in red two phrases: “Workplace Instructions” and “Job Descriptions”.

Those are powerful instruments that could be written out, and then training provided for your people to use them to produce uniform output consistently..

Such best practice training - among other benefits - ensures they know the importance of sticking with laid down procedures to achieve the farm's goals.

There will be things that you will be able to monitor, that will help you determine whether or not your people are doing that.

Of course, no one who is NOT competent to be on your farm, in terms of following the established guidelines, will be allowed to operate in the process.

There’s an aspect of what I’ve said here that has to do with your ability to reduce your costs of operation.

More often than not, you cannot aim to increase the prices at which you sell.

Instead as a smart business owner – especially one running a farm operation – look for ways to reduce your costs of operation.

Specifically, your variable costs.

That means you will develop, and commit - on a long term basis - to looking for ways and means to reduce the cost at which you turn out your farm produce.

And that again has to do with the best practice SOP.

Exploring Variable Costs Reduction Initiatives (Ideas You Can Use)

There are so many ways you can reduce your operating costs.

Now this has to do with teaching your people and yourself how to think up ideas – new ideas and better ideas for running your operations.

For instance, a lot of people are exploring using complementary feeding ingredients. Others are exploring using Indomie noodles waste, and even cooked chicken intestines.

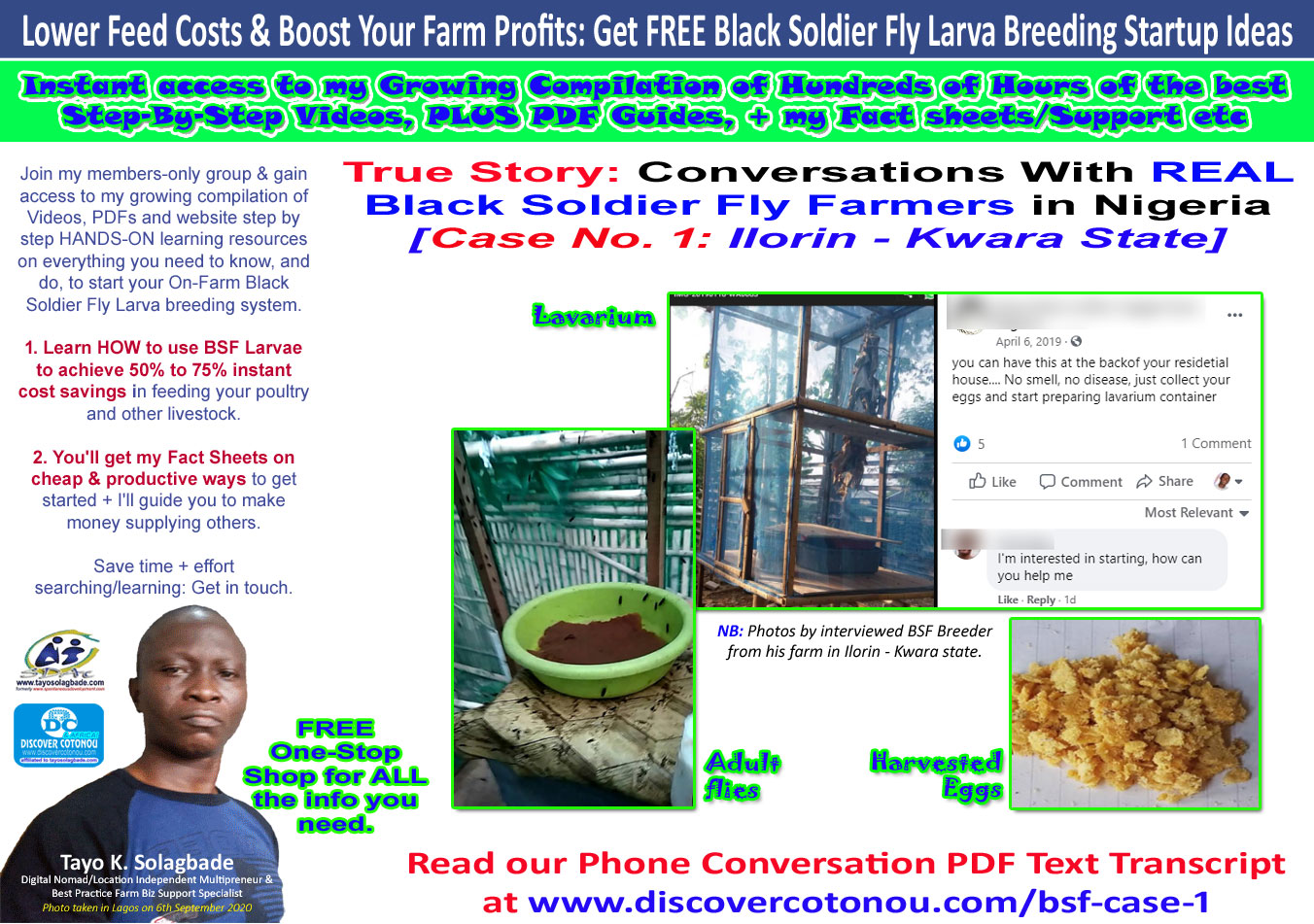

But even more promising has been the concept of INSECT BREEDING, especially maggots rearing (See video below)

In particular, Black Soldier Fly (BSF) Farming has proven to be a huge cost saver for farmers. Click images below to learn more.

But how do you go about systematically doing that, to achieve lower cost of operation on your farm, therefore achieving increased profits?

Those are things that adopting an intelligent BOPMS - especially the aspect of entrenching SOPs - can allow you to achieve. (Get in touch if you'd to book an session in which I can elaborate on what a full BOMPS project implementation requires).

But if you don’t want that...

If you just want a simple approach to it, that can still help you, look at the 3 yellow boxes in the mind map e.g. Tracking your expenditure and income; having KPIs in place, and using a software to track them in charts and in form of data.

Those would help you go far in monitoring your farm operations and getting the best results.

Final Words

The above is meant to give you an overview of what a BOPMS™ for Farm Business Performance Improvement is about.

If you decide you want to learn more, click here to watch related videos, and read over 10 articles that offer more details.

On that same page, you'll be able to send your enquiry to me, using a web contact form I've setup there.

Good luck!

Master KPI Computation and Interpretation to Boost Your Farm’s Profits [8 Week BOPMS™ COACHING PROGRAM] - FREE FOR INNER CIRCLE MEMBERS

RELATED RESOURCES

1. Your Business Should Free You, Not Restrict You

http://tayosolagbade.com/sdnuggets/your-business-should-free-you-not-restrict-you/

2. Adopt Standard Operating Procedures to Succeed More With Less Effort (This Works for Solopreneurs and Large Organisations)

3. Five Essential Poultry Layer Farm Production Records

4. Practical Poultry Farm Business Performance Calculations

http://ezinearticles.com/?Practical-Poultry-Farm-Business-Performance-Calculations&id=2635011

5. Five Powerful Tools for Accurately Measuring Your (Farm) Business’ Health

6. Five Proven Ways to Boost Farm Profits without Raising Prices

7. Producing Good Catfish is Important, But Finding Good Buyers is Imperative!

8. Reducing Catfish Feeding Costs (A Secret Weapon) – Part 1 of 2

9. Reducing Catfish Feeding Costs (A Secret Weapon) – Part 2 of 2

10. Top 10 Ingredients Used in Livestock Feed

http://africabusinesscommunities.com/features/top-10-ingredients-used-in-livestock-feed.htm

11. PII 015: To Succeed, Your Farm Does Not Just Need a Software – It Needs a BOPMS!

12. PII 020: A BOPMS™ Will Enable You Run Your Farm Business Profitably Even When You’re Away!

Master KPI Computation and Interpretation to Boost Your Farm's Profits [8 Week BOPMS™ COACHING PROGRAM]

Master KPI Computation and Interpretation to Boost Your Farm's Profits [8 Week BOPMS™ COACHING PROGRAM] KPI = Key Performance Indicators BOPMS™ = Best Operatin…

Adopt Custom Best Practice Systems to Boost Your Farm's Output and Profits [TIP: Watch New Mind Map Based Video Explanation of Tayo Solagbade's Best Operation Process Management System - BOPMS™]

lTIP: The mind map based video explanation now offered from this page is actually a re-RECORDING to replace the original version that (strangely) became "Not F…

NOW BACK ON YOUTUBE [Watch Part 1 of 3] What is a BOPMS™ for Profitable Farm Improvement? (Mind Map Explanation By Tayo Solagbade)

FYI = This is actually a re-RECORDING to replace the original version published about 4 years ago, that (strangely) became "Not Found" here in my Youtube chann…

16. PII 015: To Succeed, Your Farm Does Not Just Need a Software – It Needs a BOPMS! [TRUE STORY]

PII 015 [TRUE STORY]: To Succeed, Your Farm Does Not Just Need a Software - It Needs a BOPMS!

Below is a message I received from a Farm CEO few days ago, asking for a software solution: "...I'm currently running a piggery business with no record keeping…

Greetings from Idaho! I'm bored to death at work so I decided to browse your website on my iphone during lunch break.

I enjoy the information you provide here and can't wait

to take a look when I get home. I'm shocked at how

quick your blog loaded on my phone .. I'm not even using WIFI, just 3G

.. Anyways, awesome site!

Thanks for your kind words. Cheers 🙂